三捷率先推出带厚度监测功能的焊锡膏自动添加装置

带锡膏测厚功能的自动加锡装置,系深圳市三捷机械设备有限公司自主研发,具备自主知识产权的一种新型自动化设备。该装置继承了三捷机械自动加锡各项优点,如:兼容各类主流厂商的瓶装锡膏,无需客户更改特殊包装;采用倒立式出锡,无需在锡膏瓶的底部钻孔;程序控制移动式加锡等。在此基础上,新增了锡膏高度实时侦测功能。该功能有如下突出的特点:

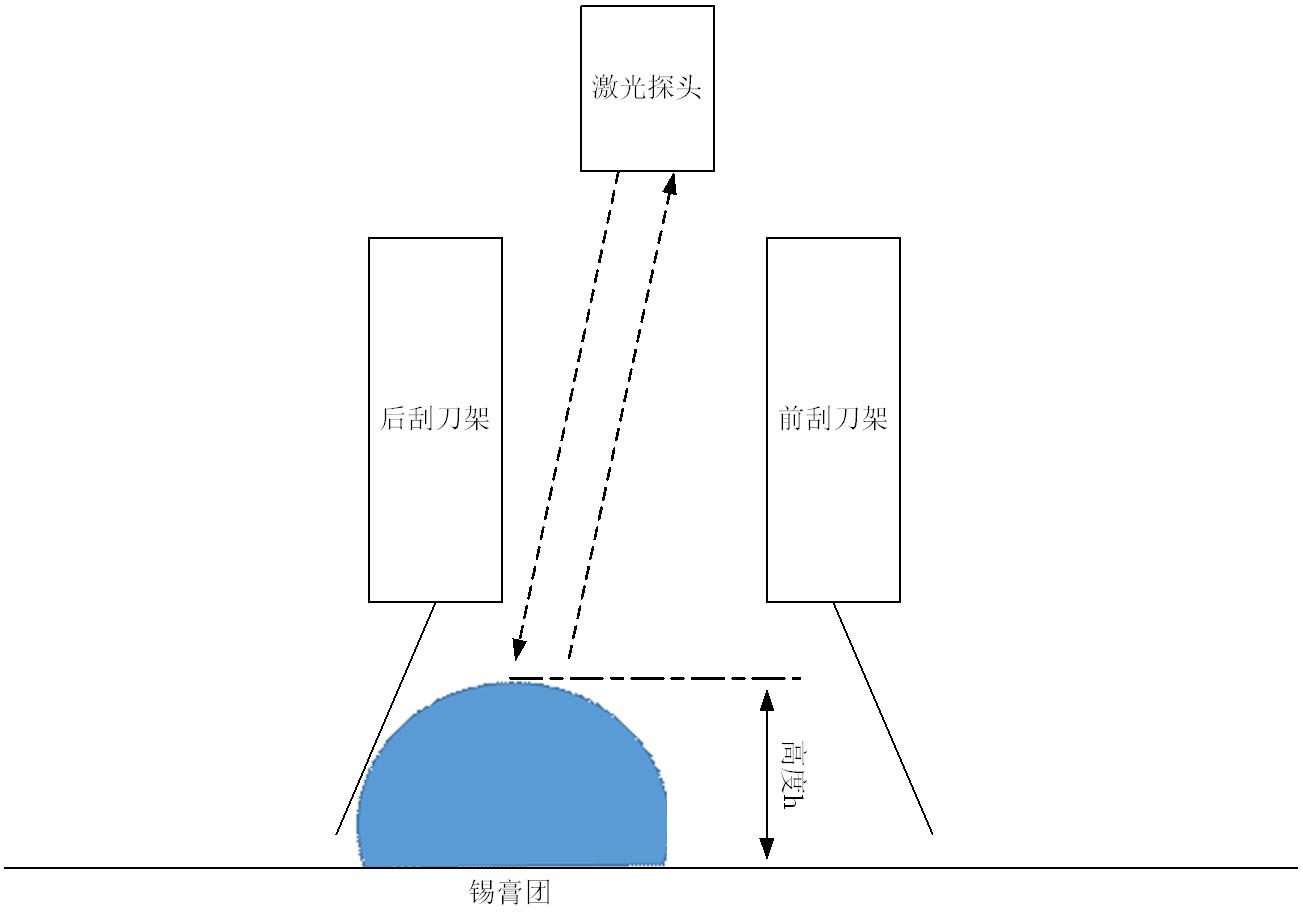

激光测厚。该装置采用激光反射传感器,实施监测钢网上焊锡膏的滚动直径(图1所示),当所测的锡膏高度低于设定值时,即触发加锡。相比于传统的按照PCB板计数的功能,该功能对自动加锡装置作闭环控制,实时监测钢网上的锡膏厚度,测量精度可达1mm, 避免用计数方式设定加锡频率而带来的锡膏添加量不足的问题。

图1. 激光反射传感器实施监测钢网上焊锡膏的滚动直径

通过实时监测焊锡膏的滚柱高度,对钢网上的锡膏实现了闭环控制(图2)。可以始终保持钢网上有定量的锡膏,最大程度上提升了保证品质。

图2. 实时监测焊锡膏的滚柱高度,对钢网上的锡膏实现了闭环控制

节省焊锡膏。挤压倒立式出锡,可使空瓶的锡膏残留量少于6克(图3)。减少浪费。

图3. 空瓶的锡膏残留量少于6克

提高印刷效率。系统通过传感器感知刮刀的上下运动,硬件和软件均独立加装于印刷机之外。加锡时序位于2次PCB板进板中间的间隔,或者印刷机擦拭钢网的时间片刻,无需额外占用印刷机的生产时间,从而提升效率。

安全环保。自动加锡可以有效避免操作员工同锡膏直接接触,最大程度上降低了焊锡膏里挥发性溶剂和重金属物质对人体的伤害,保证人员健康。

通过加装三捷机械的自动加锡系统,可以使客户的锡膏添加不再依赖于人工,另外,对于锡膏品种如锡膏种类、成分特性、有效期等,以及加锡过程参数如钢网上的实时锡膏量、加锡频率、每次的添加量等指标都可以做有效管控。在可预见的将来,三捷机械的自动加锡系统会被推广并广泛应用于我国的SMT各行各业,从而为我国的工业制造尽一份绵薄之力。

Dispensing Unit with Paste Roll Height Monitor

Abstract: By installing auto paste dispenser with Paste Roll Height (PRH) monitor, the solder paste dispensing can be controlled as a close-loop system. Once the paste roll height is below the setting value, it will trigger automatic dispense.

Author: ShenZhen Synergies Machinery Co., Ltd

Date: Mar-22-2018

The solder paste dispenser with Paste Roll Height (PRH) monitor is a close-loop dispensing system developed by Shen Zhen Synergies Machinery. Compared to conventional units, the system is highlighted by the following strengths:

Compatible with different kinds of solder paste jars. The solder paste is squeezed by a special designed piston and there’s no need to drill holes underneath of the jar.

Dispensing on the fly. The solder paste dispensing trajectory can be programmed so that the solder paste can be evenly dispensed onto the stencil, the paste rolls are fully mixed and thus ensures best printing quality.

Real-time paste roll monitor. By mounting one or several laser-beam sensors around the paste roll, the system can inspect the real-time paste roll height. Once the paste roll height is below the setting value, it will trigger automatic dispense. Manufacturing defects caused by insufficient solder paste which is mostly caused by incorrect dispensing frequency can be eliminated by this close-loop system.

By installing auto paste dispenser with PRH monitor, the SMT printing progress can be greatly improved by:

The printing quality will be improved as the solder paste on the stencil can be maintained by a certain amount through the PRH monitoring.

Less residue on the empty jar, less waste. The residue solder paste on the jar can be squeezed as less as 6g, which reduces possible waste effectively.

More ergonomic and environmental. Operator no longer needs to touch the solder paste as it is enclosed by a chamber. This eliminates the risk of exposing the volatile solvent as well as the toxic metallic substances inside of the solder paste to the operators’ skin or eye.